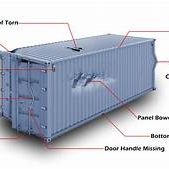

Through many years of experience (began as SeaCanSolar) in the field we noticed that there were many issues to address around the logistics of handling SeaCans (sea containers). We noticed that the SeaCans cannot easily move (forward, backward, pivot) SeaCan around a jobsite to the point of work; and when operators attempt to move these SeaCans they often get damaged often in transport (especially fully loaded), get ruined sitting on the ground or moved around without a sled underneath where air and moisture is not free to flow around the structure of the SeaCan.

www.Boks.LTD

Whitchurch-Stouffville

Ontario

l4a7x5

We often found the SeaCans were prone to animal infestation, mold and insects making homes beneath the SeaCans and in the core structure (ribs/cross members and frame)

During moves we often found the bottom ribs/cross members and floorboards rot/corrode rapidly from all the moisture and/or environmental conditions i.e. soft wet soils, manure and farm applications, frozen/thawing ground etc. In that we found the super structure and upper body of the SeaCan tend to corrode and fall apart quickly without moving air flow around the SeaCan unit/s. we have also addressed issues during moves where the core frame of the SeaCan becomes softened and dangerous to lift and move over time; thus ending up unloading all goods inside the SeaCan and an on the spot crushing, removing, recycling of the SeaCan which is costly.

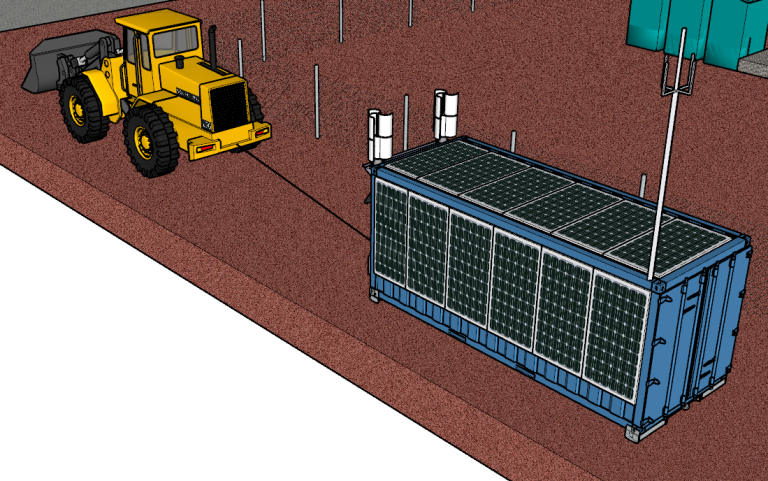

Having been on many large sites moving containers requires costly special equipment particularly when loaded (ie. heavy duty forklift, crane, flatbed/tilt'n load)

Logistical issues when we found SeaCans without a sled beneath are often locked into tight spaces and cannot be moved or loaded. We then normally must convene a crane or a heavy lift forklift.

We found that built out SeaCans sustain significant damage and/or lose parts of the assembly - i.e. propane for hvac, tooling for specialty applications, gensets etc.

For those sites that did not understand how the SeaCans are constructed we found that the super structure on the SeaCans often becomes twisted and the superstructure offset due to corner or front/back side dragging without a Sea Container Sled. Hinges, locking bars, guides, and brackets, fitted doors/windows often stop functioning because of the ISO SeaCan frame being bent because it was not handled with proper equipment.

We have had to bring in equipment particularly in support of SeaCans as they cannot be dragged or moved easily over harsh environments – quarries, mines, forests, farms, frozen bodies of water etc. We found that project managers and planners never consider the removal of the equipment when the job is done and is usually a cost they do not anticipate.

We sat back and watched the number of operational deficiencies and huge costs associated to a few SeaCans can amount to as they cannot be mobilized and demobilized using limited resources over short and long distances.

We thought we can address a lot of the issues from a well-built piece of apparatus that would address all the issues noted.

From a tactical point of view, we knew we had to find a method to support mobilisation and demobilisation that can handle the gross weight of a fully loaded container. We had to be able to move a SeaCan with the work crews along all job sites and all surfaces. (Large and small rock, sand, soil, ice and man-made surfaces – asphalt, concrete etc.) Also be able to be moved around easily under all dimensional clearances in remote and urban conditions.

Where one of our clients were traditionally using rolling trailers which inevitably get destroyed by the end of the operation.

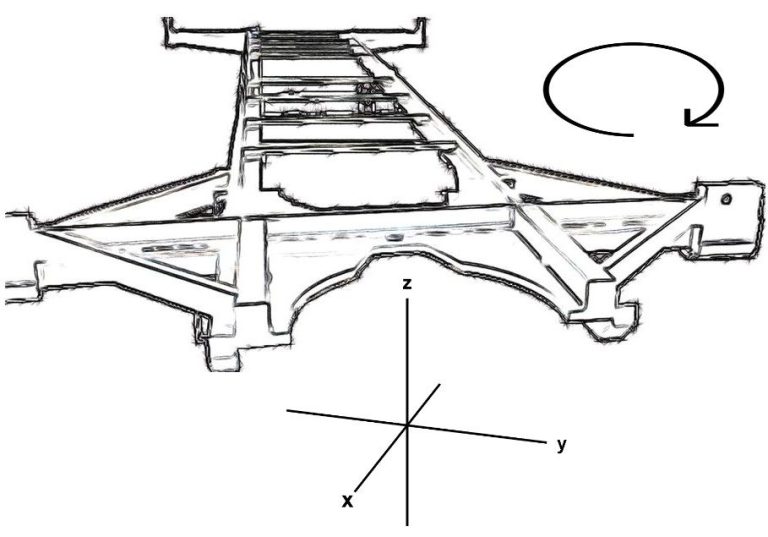

Need to meet all regulations to be lifted and used in high-rise construction, pipeline and rail and highway construction, mining applications and large agricultural operations; essentially, we must design for the conditional extremes. Therefore, addressing x, y and z axis movement.

We need to be able to move SeaCan across all terrain (broken or flat asphalt/concrete, rock, soil, sand) easily with almost any machinery on site. (using limited resources and maintain operational efficiency). We found both a front-end loader and backhoe being the most common of applications.

We found that the superstructure needs to be supported and to easily be able to level the containers out onsite or build a system that self levels.

We also want to use standard CSC/ISO SeaCan equipment (ie. joiners and clasps) as it exist in abundance in the shipping and transport industries.

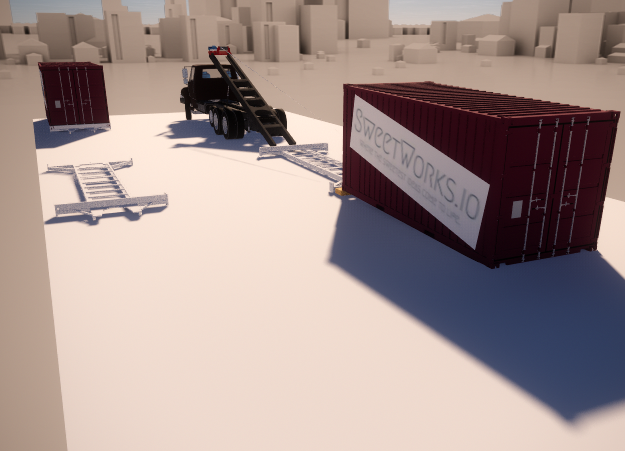

Finally, we determined that the SeaCan had to be able to be picked with a roll off truck, J Hook Lift truck or a flat bed/tilt and load in tight quarters from the front and back without destroying any equipment with one operator. Also be able to pull the SeaCan's from the corners; on a diagonal without causing any structural damage to the SeaCan. We chose the roll off truck adaptation as the primary focus as it is the most common, most rugged, and versatile tractor truck worldwide as they are most often used for waste disposal and are built heavier than most tractor trucks.

We took the idea to cad and to the shop and deployed prototypes in the field.

The rest is history the boks sled has spoken for itself and all the infield operators love using it as it saves them time, money and has addressed safety and risk concerns as well.